Everything You’ll Need

| Tool / Material | Solid Hardwood (Nail-Down) | Engineered Hardwood (Glue-Down) | Engineered Hardwood (Floating/Click-Lock) | Purpose |

|---|---|---|---|---|

| Tape Measure | ✔ | ✔ | ✔ | Measure layout and planks |

| Chalk Line | ✔ | ✔ | ✔ | Mark layout lines |

| Pry Bar | ✔ | ✔ | ✔ | Remove old flooring/baseboards |

| Moisture Meter | ✔ | ✔ | ✔ | Check subfloor moisture |

| Level | ✔ | ✔ | ✔ | Ensure even subfloor |

| Spacers | Optional | ✔ | ✔ | Maintain expansion gap at walls |

| Flooring Nailer / Stapler | ✔ | ✘ | ✘ | Secure solid planks to subfloor |

| Flooring Adhesive | ✘ | ✔ | ✘ | Glue engineered wood to subfloor |

| Trowel (for adhesive) | ✘ | ✔ | ✘ | Spread adhesive evenly |

| Click-Lock Installation Kit | ✘ | ✘ | ✔ | Includes tapping block, pull bar, spacers |

| Miter Saw | ✔ | ✔ | ✔ | Make crosscuts on planks |

| Jigsaw / Oscillating Tool | ✔ | ✔ | ✔ | Trim around obstacles |

| Safety Glasses | ✔ | ✔ | ✔ | Eye protection while cutting |

| Knee Pads | ✔ | ✔ | ✔ | Comfort during install |

| Underlayment / Vapor Barrier | Depends on subfloor/type | ✔ (moisture barrier) | ✔ | Reduces noise & moisture issues |

| Shop Vac or Broom | ✔ | ✔ | ✔ | Keep area clean while working |

Step 1: Prepare the Space

Take Off Baseboards and Old Flooring

Start by taking away any old flooring and baseboards to see the subfloor. This makes a nice surface and lets the hardwood expand at the edges.

Use a pry bar to gently lift baseboards without hurting the wall so you can put them back later. Remove any carpet, vinyl, laminate, or old hardwood, and make sure all old glue or staples are completely cleaned off.

Clean and Make the Subfloor Even

Sweep and vacuum the whole subfloor to get rid of dust, nails, trash, or glue bits. Check for dips or high spots using a straight edge or long level.

- For high spots: sand them down.

- For low spots: use a floor leveling compound to fill and smooth out uneven areas.

A flat, even subfloor is important to stop squeaks and make the floor last long.

Look for Moisture or Damage

Moisture can cause hardwood floors to fail. Use a moisture meter to test the subfloor and your hardwood planks.

- For wood subfloors: moisture content should usually be below 12%.

- For concrete subfloors: follow manufacturer limits — often below 4% with a calcium chloride test.

If the moisture is too high, stop installation and fix the issue before moving on.

Put Down Underlayment or Vapor Barrier (If Needed)

Depending on your flooring and subfloor, you might need an underlayment or moisture barrier:

- Over concrete: use a vapor barrier or underlayment with moisture protection.

- Over plywood or OSB: a rosin paper, felt underlayment, or foam pad might be suggested.

Follow the manufacturer’s requirements to avoid warranty problems and ensure the best performance. Lay the underlayment flat, without overlapping, and tape seams where needed.

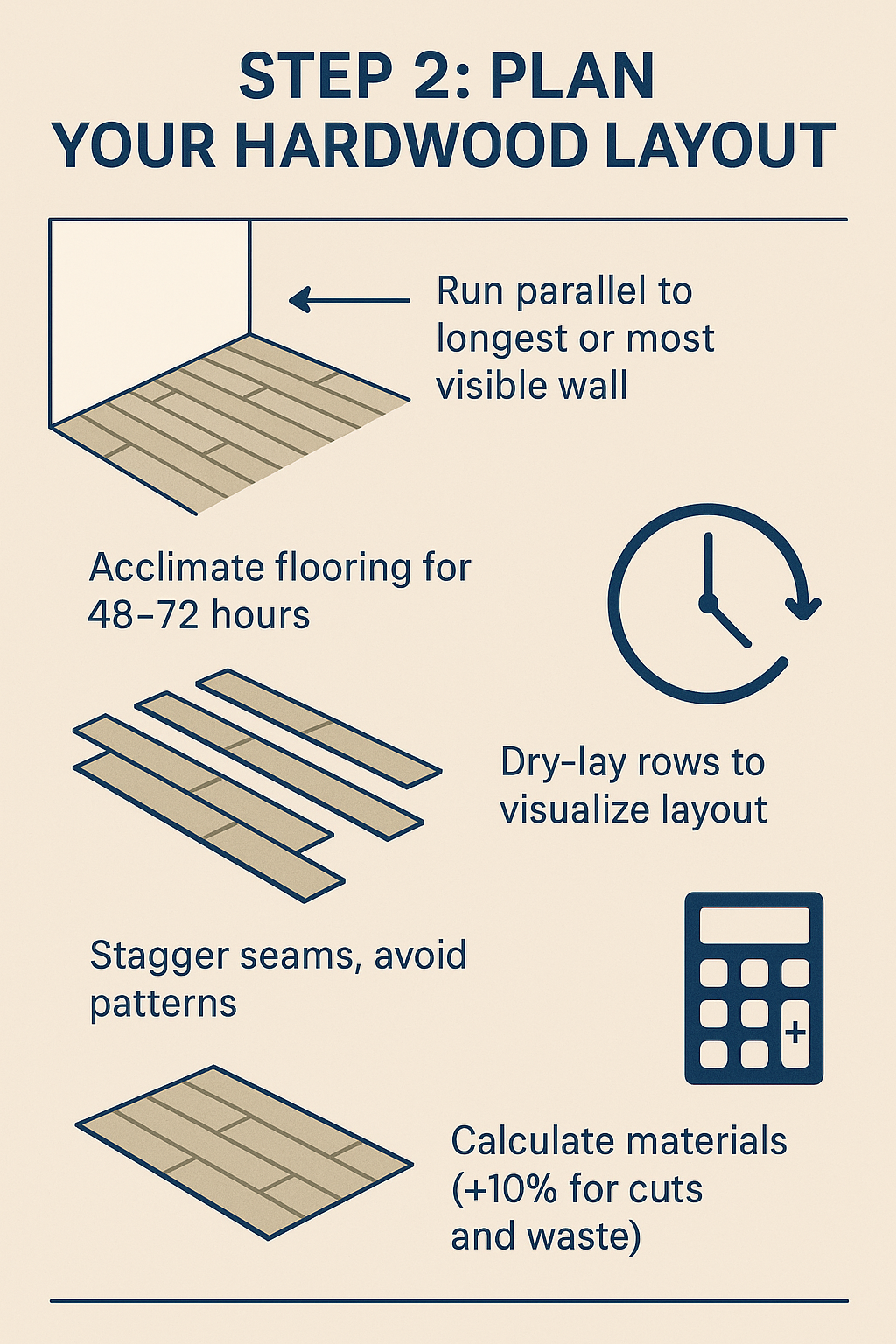

Step 2: Plan Your Hardwood Layout

Pick Your Starting Wall

In most rooms, it’s best to lay hardwood planks parallel to the longest or most visible wall so the room looks bigger. If you’re installing in more than one room, think about how the planks will connect at doorways and between rooms.

Use a chalk line to mark a straight guide along your starting wall. This helps keep your first rows straight, making sure the rest of the floor stays aligned.

Let the Flooring Adjust

Before you start, let the hardwood planks adjust to the room’s temperature and humidity for at least 48 to 72 hours. Lay the boxes flat in the room where you’ll install the floor, and open the ends for air circulation.

This helps the wood adjust to the room and lowers the chance of expanding, warping, or gapping after installation.

Try a Dry Run with a Few Rows

Lay out a few rows of boards without nailing them down to see how your design will look. This helps you:

- Make sure the design looks balanced

- Avoid having narrow planks by the walls

- Plan for things like vents or doorways

Use this time to mix boards from different boxes to spread color and grain differences evenly.

Stagger Seams and Avoid Patterns

For a natural look, stagger the ends of planks by at least 6 to 8 inches in nearby rows. Avoid repeating plank lengths or making “stair-step” or “H” shapes, as these can make seams noticeable.

Pro tip: Use different plank lengths and alternate them across rows for a more natural appearance.

Calculate Material (Add Extra for Waste)

Measure your area (length × width) and then add 10% to cover waste, mistakes, and future repairs.

If your space has odd shapes or you’re laying planks diagonally, increase the waste allowance to 12–15%.

Step 3: Choose Your Installation Method

Before you start putting down boards, choose the best way to install your hardwood flooring based on the type and subfloor. Different methods need different tools and skills.

Nail-Down Installation (Common for Solid Hardwood)

This method is good for solid hardwood on a wooden subfloor. Use a flooring nailer or stapler to attach each board.

- Best for: Solid hardwood on wood subfloors

- Tools needed: Flooring nailer, mallet, air compressor

- Pros: Very secure and lasts long

- DIY Difficulty: Moderate (needs care and the right tools)

Glue-Down Installation

Mainly for engineered hardwood on concrete, this method uses adhesive to stick boards to the subfloor.

- Best for: Engineered hardwood on concrete

- Tools needed: Flooring adhesive, notched trowel, floor roller

- Pros: Strong bond and low profile

- DIY Difficulty: Moderate to high (messy and needs ventilation)

Floating Installation (Click-Lock)

This is a favorite for DIYers using click-lock engineered hardwood. Planks lock together and “float” over an underlayment.

- Best for: Click-lock engineered hardwood on any flat surface

- Tools needed: Spacers, tapping block, underlayment

- Pros: Fast, clean, easy for beginners

- DIY Difficulty: Easy

Pro Tip: For solid hardwood on a wooden subfloor, nail-down is usually best. For engineered hardwood, floating floors are popular with DIYers because they’re easier to install without tools.

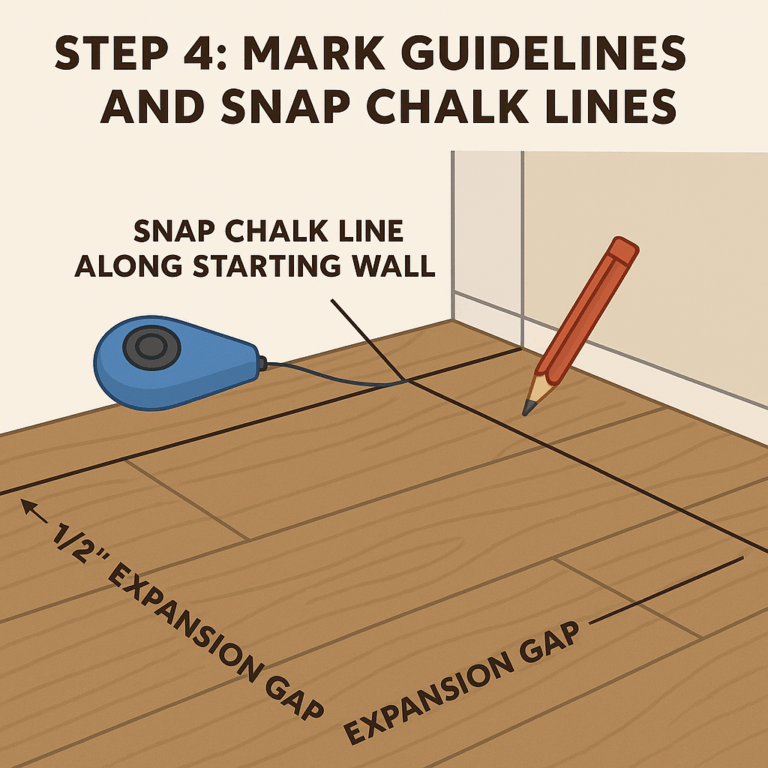

Step 4: Mark Guidelines and Snap Chalk Lines

Before you start, make a straight line to help guide your floor installation.

Mark a Line on Your Starting Wall

Find your starting wall, usually the longest or main wall in the room. Measure the width of one board, including space for expansion, and mark a chalk line parallel to it. This will guide your first row.

Keep Boards Aligned with the Line

When placing the boards, keep them aligned with the chalk line. This helps keep your floor straight and prevents curves over time.

Leave a 1/2″ Space Around the Edges

Wood changes size with humidity. Use spacers to leave a 1/2-inch gap between the floor and surrounding walls or fixed items. This prevents buckling by allowing the floor to expand.

Step 5: Lay the First Row of Planks

Trim Door Jambs if Needed

Before installing the first plank, see if it needs to go under any door trim. Use a flush-cut or jamb saw to cut the bottoms of door jambs so planks fit smoothly underneath.

Start with Groove Side Facing the Wall

Place the first plank with the groove side next to the wall. This makes it easy for the next row to lock into place. Start along the longest, straight wall to keep the flooring aligned throughout the space.

Secure the First Row

Depending on how you install:

- Nail-down: Use a flooring nailer to attach boards into the subfloor through the tongue side.

- Glue-down: Apply adhesive with a trowel and press each plank firmly.

- Floating (click-lock): Angle the second plank into the first, then click to lock.

Make sure the planks fit tightly without gaps at the seams.

Use Spacers to Maintain Expansion Gaps

Place 1/2″ spacers between the planks and the wall. This gap allows for natural movement of the hardwood due to humidity and temperature changes, preventing buckling or warping over time.

Step 6: Install the Remaining Flooring

Once the first row is secured and aligned, continue laying your hardwood planks row by row.

Stagger the End Joints for Stability

For a natural, seamless look and added structural strength, stagger the end joints of each row by at least 6 inches. Avoid aligning joints across consecutive rows, as this weakens the floor and creates a repetitive pattern.

Use a Tapping Block for a Tight Fit

Place a tapping block against the edge of each plank and gently tap it with a mallet to close gaps. This ensures each board is snug against the last without damaging the tongue or groove.

Secure Boards Based on Your Method

- Nail-down: Drive nails through the tongue at a 45° angle every 6–8 inches.

- Glue-down: Spread adhesive evenly and press planks firmly into place.

- Floating floor: Click boards together end-to-end and side-to-side.

Check for Level Frequently

Every few rows, use a level to ensure the floor remains flat. Adjust as needed before proceeding to prevent long-term issues.

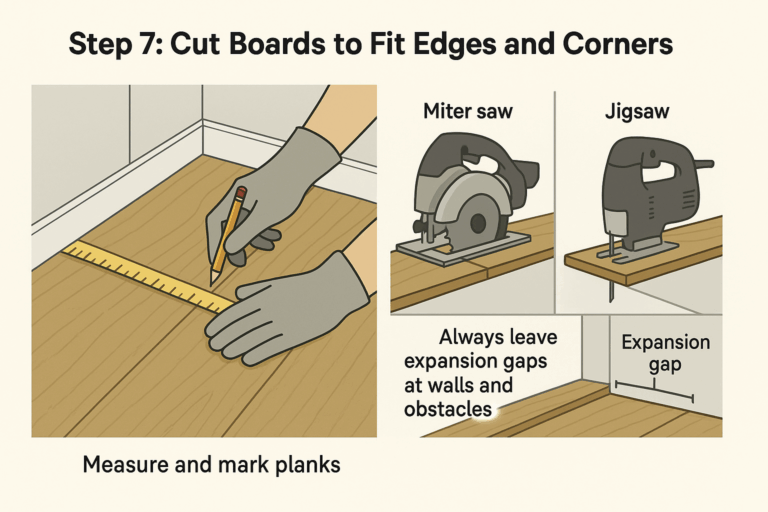

Step 7: Cut Boards to Fit Edges and Corners

As you approach the walls or obstacles in the room, you’ll need to custom-cut the final planks for a perfect fit.

Measure and Mark Carefully

Use a tape measure to determine the exact space remaining, subtracting 1/2″ to allow for an expansion gap. Mark your plank accordingly with a pencil or chalk.

Use the Right Saw for the Job

- Miter saw: Best for clean, straight cuts.

- Jigsaw: Ideal for curved cuts around vents, door frames, or irregular shapes.

Always cut on a stable surface and wear safety glasses to protect your eyes from dust and debris.

Maintain Expansion Gaps

Leave a consistent 1/2″ gap between the flooring and all vertical surfaces — including walls, pipes, and cabinetry. This allows the hardwood to naturally expand and contract without buckling.

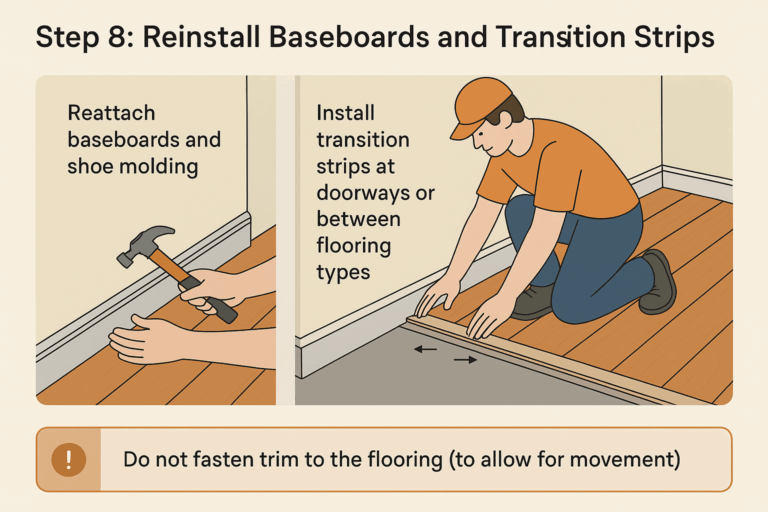

Step 8: Reinstall Baseboards and Transition Strips

Reattach Baseboards and Shoe Molding

Once your hardwood planks are installed and secure, it’s time to give the room a clean, finished look. Reinstall the baseboards along the perimeter of the room. If your original trim included shoe molding, reinstall that too for a polished finish.

Install Transition Strips

At doorways and where hardwood meets another flooring type (like tile or carpet), install the appropriate transition strips. These include T-moldings, reducers, or threshold transitions depending on the height and material of the adjacent flooring.

Leave Room for Movement

When nailing or gluing down trim, make sure not to fasten it directly to the hardwood flooring. Doing so can restrict expansion and contraction and may lead to buckling. All trim should be secured to the wall or subfloor—not the floating floor itself.

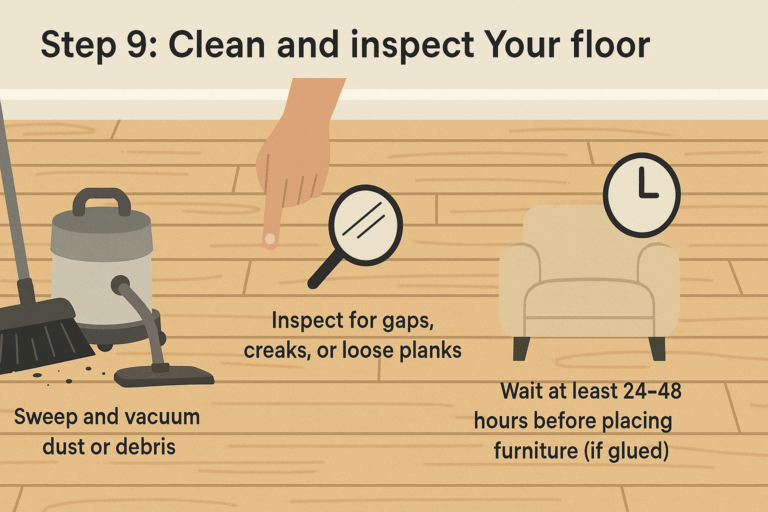

Step 9: Clean and Inspect Your Floor

Once installation is complete, take the time to clean and inspect your new hardwood floor to ensure everything is in top shape before use.

Sweep and Vacuum Thoroughly

Remove all sawdust, wood chips, and debris using a broom or vacuum with a soft-brush attachment. This not only gives you a clear view of the floor but also prevents scratches during inspection or furnishing.

Inspect for Issues

Check for visible gaps, uneven planks, or creaking sounds as you walk across the floor. Use a tapping block to snug up any slightly misaligned boards or consult your installation method if adjustments are needed.

Let the Floor Settle

If you used glue-down installation, wait at least 24–48 hours before placing furniture or rugs. This allows the adhesive to fully cure and prevents shifting.

Pro Tips for a Successful Hardwood Installation

Getting professional-looking results with hardwood flooring is all about preparation and precision. These tips will help you work smarter and avoid frustration:

- Always test for moisture using a moisture meter before installation — this helps prevent cupping or buckling later.

- Use knee pads to protect your joints during long hours of floor work, and ensure proper ventilation if you’re using adhesives.

- Check alignment every few rows to make sure planks stay straight and flush.

- Work in manageable sections rather than rushing the entire room at once — this helps maintain quality.

- Take your time on cuts. Clean, accurate cuts make all the difference in creating tight seams and professional results.

Common Mistakes to Avoid When Installing Hardwood

Even experienced DIYers can run into issues if these common missteps aren’t avoided:

- Skipping the acclimation period can cause the wood to expand or contract after installation.

- Neglecting subfloor moisture and flatness leads to instability, noise, or gaps.

- Failing to stagger seams weakens the structural integrity and creates an uneven appearance.

- Nailing too close to the edge of the plank can cause splits or cracks.

- Forgetting to use spacers leaves no room for expansion, which can lead to buckling.

DIY vs. Professional Hardwood Installation

Installing hardwood flooring yourself can be a rewarding and cost-saving project — but it’s not the right approach for everyone. Here’s how to decide if you should roll up your sleeves or call in the pros.

DIY Pros:

- Lower total project cost

- Full control over pace and schedule

- Great satisfaction from doing it yourself

DIY Cons:

- Physically demanding and time-consuming

- Requires precision, planning, and specialized tools

- Mistakes can be costly to fix

Professional Installation Pros:

- Fast, expert results with minimal disruption

- Includes subfloor prep, leveling, and cleanup

- Often backed by workmanship warranties

Professional Installation Cons:

- Higher labor cost

- Less flexibility and control over timing

📊 Side-by-Side Comparison Table

| Feature | DIY Installation | Professional Installation |

|---|---|---|

| Average Cost per Sq Ft | $3 – $8 (materials + tools) | $7 – $18 (includes labor) |

| Best For | Budget-conscious, handy homeowners | Busy homeowners, large or complex jobs |

| Time Commitment | Several days or weekends | 1–2 days (typical) |

| Risk of Mistakes | Moderate to high | Low |

| Tool Investment Required | ✔ | ❌ (provided by installer) |

| Satisfaction | High (if done well) | High (with professional finish) |

👉 For a full breakdown of costs, methods, and scenarios, visit our Hardwood Flooring Cost Guide

Do You Need Professional Help With Your Hardwood Flooring Installation Project?

Now that you’ve learned how to install hardwood flooring step-by-step, you’re well on your way to creating a warm, timeless look that adds value to your home. But if you’d prefer to skip the heavy lifting — from precise cuts to subfloor prep — we’re here to help.

Our expert flooring installation team handles every detail with care, whether it’s nail-down, glue-down, or floating hardwood. We’ll make sure your floor is level, secure, and built to last — without you breaking a sweat.

Contact us today to schedule your free in-home consultation and see if we serve your area!